| Volume | 750ml |

|---|---|

| Particles | Finishing |

| Viscosity | 3 |

| Fluid color | White |

| Characteristics | Non-silicone/wax-free |

- FE News»

- PPS News»

- Oct. 31, 2024

- [News Release R-1020] Release of "ECHELON Zen-Xero DYNAMIX”

- May. 15, 2024

- [News Release R-1019] Release of "ECHELON Ver.3.0”

- Oct. 02, 2023

- [News Release R-1018]Compound that achieves a genuine finish Full Renewal of “KATANA” Series

- Jun. 27, 2023

- [News Release] A final finishing compound that achieves a beautiful wet gloss. "KATANA DARK-SHOT" is Released.

- May. 22, 2023

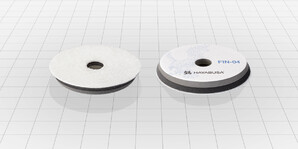

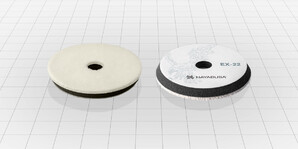

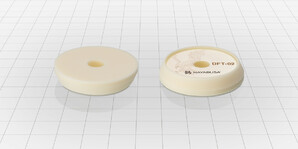

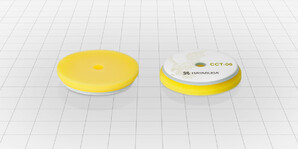

- [News Release] Full renewal of buffing pad category Brand integrated into HAYABUSA

Axalta PL C7

Properties of stannic oxide (SnO2)

1. High relative density

Stannic oxide is 1.7 times more dense than alumina (the most commonly used abrasive particle), and 2.6 times more dense than silica. Because of that, it starts to work on polished surfaces more quickly, increasing the efficiency of the polishing process. In addition, it causes little dusting during buffing.

2. Low hardness

Stannic oxide is less hard than alumina, allowing for a gentler polish.

3. Long effective polishing time

The abrasive particles adapt to water, oil and the buffing pad easily, lengthening the effective polishing time. (Because alumina does not work well with water, the polishing efficiency is dependent on the moisture in the compound being low.)

・Can be used as a finishing compound for any kind of paint, from the latest high-solid and high-grade paints to general restoration paints.

・Polishing of scratch-resistant clear coatings and deep gloss restoration is only possible with PL C7.

Comparison of the effective polishing time of PL C7 with typical compounds (for illustrative purposes only)

The graph shows the speed of the increase in cutting power and the length of the effective polishing time. PL C7 reaches an effective level of cutting power quickly, allowing it to maintain effectiveness for a longer period of time. Conversely, general compounds are slow to reach an effective level of cutting power and only work well within a short window (the efficiency rises after the moisture in the compound decreases).

*The manufacturer has changed from DuPont to Axalta.