| Set contents |

Hard Barrier X-OVER (50mL) x2 Sponge x6 ”Application Complete” sticker x6 Certificate of Application x6 *This product contains 2 sets *Estimated amount for application on regular passenger vehicle: 15mL approximately |

|---|

- FE News»

- PPS News»

- Oct. 31, 2024

- [News Release R-1020] Release of "ECHELON Zen-Xero DYNAMIX”

- May. 15, 2024

- [News Release R-1019] Release of "ECHELON Ver.3.0”

- Oct. 02, 2023

- [News Release R-1018]Compound that achieves a genuine finish Full Renewal of “KATANA” Series

- Jun. 27, 2023

- [News Release] A final finishing compound that achieves a beautiful wet gloss. "KATANA DARK-SHOT" is Released.

- May. 22, 2023

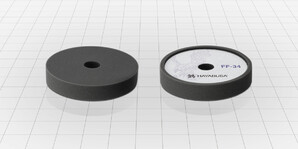

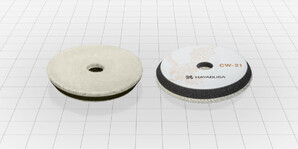

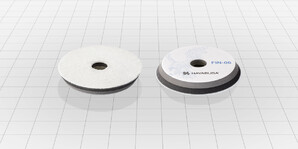

- [News Release] Full renewal of buffing pad category Brand integrated into HAYABUSA

Linda Hard Barrier X-OVER

*The following is from the manufacturer’s materials

■High hardness coating: hardness 7H

With its special proprietary manufacturing method, it can form a glass coating with a triple layer structure. It forms its tough yet flexible hard coating with high-quality polysilazane + highly concentrated siloxane + fluorine. *Hardness 7H (according to in-house testing)

Scratch resistance testing

After attaching a microfiber cloth to the surface roughness measurement device and rubbing it across each painted plate 2000 times, Hard Barrier X-OVER proved to have a strong physical effect and excellent scratch resistance.

■High gloss: transparent heavy pressure membrane

Using carefully selected, high-quality, low-molecular-weight siloxane to completely fill in the imperfections in a painted surface provides a superior leveling effect. While preserving the natural beauty of the paint, it achieves a finish of the highest class, with a deep, elegant luster and advanced water-repellency which allows water to flow right off.

Checking the luster

Hard Barrier X-OVER had strong luster and shine.

■High durability

This product uses a carefully selected, high-quality glass component. Additionally, high-quality polysilazane + siloxane glass component + 3 types of composite fluorine are hybridized as a new technology in order to provide a stronger adhesion and greater durability. *Please confirm using the accelerated weather resistance test data.

Outdoor exposure test

Light from a xenon arc lamp was shone on the test surface using an accelerated weather resistance testing machine. The contact angle was measured every 150 hours. Hard Barrier X-OVER maintained hydrophobicity equivalent to approximately 1 year. (150 hours = 1 month equivalent)

Washing resistance test

Using a surface roughness testing machine, the surface was washed 400 times using our company’s UC-ECO 2%, and changes in the contact angle and fall angle were measured. Hard Barrier X-OVER maintained superior water-repellency and water shedding when compared to a vehicle with no application. *A higher value for contact angle indicates greater water-repellency, whereas a lower value for fall angle indicates greater water shedding capability.

■Dirt resistance

The TFI technology forms 3-dimensional bonds of 3 types of fluorine on the top coat, forming a special coating which protects from all types of external contaminants and offers maximum effectiveness.

Outdoor exposure test

The left half was coated and the sample was left outdoors for approximately 5 months. The coating of Hard Barrier X-OVER reduced the adhesion of contaminants due to the elements.

■Application method: dry or wet

*Protective eyewear, rubber gloves, and rubber protective clothing must be worn when working with this product.

- Washing and undercoat preparation:

- 1. Remove any dirt from the vehicle by washing with a car shampoo.

- 2. After rinsing clean with cold water, wipe the surface of the vehicle body.

- 3. Prepare the undercoat as required by the state of the paint surface (removing iron dust, polishing, degreasing).

- For dry application:

- 1. Before applying the coating, remove any moisture from the body using an air blower.

- 2. Take a suitable amount on a soft cloth or sponge and spread it evenly over the surface.

- 3. Wet a soft cloth then wring out most of the moisture before using the damp cloth to wipe the surface. Then use a soft, dry cloth to wipe off any excess while checking for and correcting any unevenness.

- For wet application:

- 1. While the vehicle is still wet after washing, take a suitable amount on a soft cloth or sponge and spread it evenly over the surface.

- 2. Perform the same tasks as in step 3. of the dry application process above.

- *Please perform the application indoors (somewhere unaffected by the elements).

- *Please perform the application separately for each panel: hood, roof, etc.

- *The curing speed may vary due to humidity or temperature. Please check on the hardening process while you work.

- *It takes 12 hours after application for a full cure. Please do not touch the surface or allow water to contact it during that period.

- *Due to the properties of the products, sediment may appear. This does not indicate a quality issue.

| Approximate start time for curing of coating | |

|---|---|

| Summer and rainy season | 15 minutes |

| Winter | 35 minutes |

| Other | 20 minutes |