- FE News»

- PPS News»

- Oct. 31, 2024

- [News Release R-1020] Release of "ECHELON Zen-Xero DYNAMIX”

- May. 15, 2024

- [News Release R-1019] Release of "ECHELON Ver.3.0”

- Oct. 02, 2023

- [News Release R-1018]Compound that achieves a genuine finish Full Renewal of “KATANA” Series

- Jun. 27, 2023

- [News Release] A final finishing compound that achieves a beautiful wet gloss. "KATANA DARK-SHOT" is Released.

- May. 22, 2023

- [News Release] Full renewal of buffing pad category Brand integrated into HAYABUSA

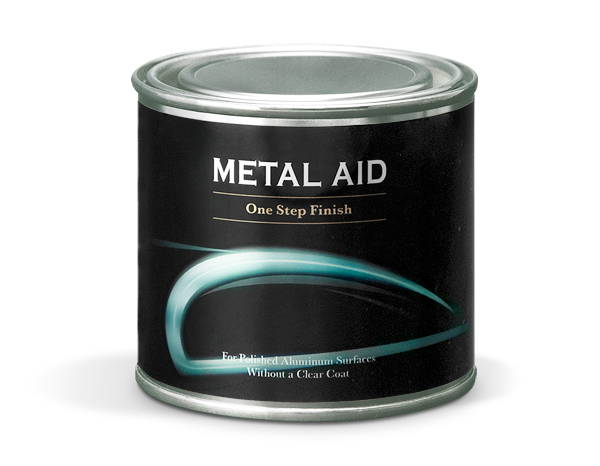

METAL AID Series

One Step

Chrome One Step Finish is a multipurpose finish that can handle everything from polishing to finishing in one step. This finish will restore the gloss to chrome metal moldings (window moldings, roof rails, etc.) that have begun to deteriorate, as is often seen on European cars. When polishing moldings that have deteriorated, use this finish first. Depending on the condition of the molding, it is possible to use this for everything from polishing to finishing.

In the interest of improving work efficiency, we separately tested the process of polishing with sand paper followed by polishing and finishing with an abrasive.

Test 3. Polishing with waterproof sand paper

Polishing with fingertips using general P1000 waterproof sand paper

Test results

Unsurprisingly, the scraping of the sand paper scratched and whitened the surface. The anodic film was worn away in some places, exposing the aluminum base. Afterwards, we polished the surface with METAL AID, but the sand paper marks remained and could not be removed. The surface gloss also remained somewhat cloudy. While results will vary with the hardness and condition of the material, it can be concluded that the risks for polishing molding in this way are challengingly high.

Test results

Unsurprisingly, the scraping of the sand paper scratched and whitened the surface. The anodic film was worn away in some places, exposing the aluminum base. Afterwards, we polished the surface with METAL AID, but the sand paper marks remained and could not be removed. The surface gloss also remained somewhat cloudy. While results will vary with the hardness and condition of the material, it can be concluded that the risks for polishing molding in this way are challengingly high.

Test 4. Polishing with P1500 Tolecut

P1500 Tolecut was applied to a Toleblock S for polishing by hand

Test results

Like the waterproof sand paper, the surface was scratched and whitened, but the marks were fine and the surface did not appear overly scraped. Afterwards, we polished the surface with METAL AID, which removed all of the marks from Tolecut. Compared to using METAL AID alone, the same finish was achieved in less time. If moldings are left as is after being polished and restored, they will eventually begin to deteriorate again. For that reason, taking measures to protect moldings could be considered more important than protecting painted surfaces. In the next section, we will explain how to effectively protect moldings.

Test results

Like the waterproof sand paper, the surface was scratched and whitened, but the marks were fine and the surface did not appear overly scraped. Afterwards, we polished the surface with METAL AID, which removed all of the marks from Tolecut. Compared to using METAL AID alone, the same finish was achieved in less time. If moldings are left as is after being polished and restored, they will eventually begin to deteriorate again. For that reason, taking measures to protect moldings could be considered more important than protecting painted surfaces. In the next section, we will explain how to effectively protect moldings.